The Industrial Internet of Things (IIoT) is a rapidly growing market that is expected to reach $500 billion by 2025.

IIoT is the use of internet-connected devices to collect and analyze data from machines and other physical assets. This data can be used to improve operational efficiency, reduce costs, and improve safety.

There are a number of factors driving the growth of IIoT, including:

- The increasing availability of low-cost sensors and other devices

- The growing demand for real-time data analytics

- The need to improve operational efficiency and reduce costs

- The increasing focus on safety and security

IIoT is having a significant impact on a wide range of industries, including manufacturing, energy, healthcare, and transportation. As IIoT continues to grow, it is expected to have an even greater impact on the global economy.

5G and Manufacturing: The Next Frontier in Industry 4.0

5G is the next generation of cellular networks, and it is poised to revolutionize manufacturing. 5G offers a number of advantages over previous generations of cellular networks, including:

- Increased speed: 5G can provide speeds up to 100 times faster than 4G LTE.

- Reduced latency: 5G can provide latency as low as 1 millisecond.

- Increased capacity: 5G can support up to 100 times more devices than 4G LTE.

These advantages make 5G ideal for a wide range of Industry 4.0 use cases, including:

- Real-time asset tracking: 5G can be used to track the location and status of assets in real time. This information can be used to improve efficiency and prevent downtime.

- Remote machine control: 5G can be used to control machines remotely. This can be used to improve safety and productivity.

- Predictive maintenance: 5G can be used to collect data from machines and devices in real time. This data can be used to predict when machines will need maintenance, which can help to prevent downtime.

5G is the next frontier in Industry 4.0, and it has the potential to revolutionize manufacturing. As 5G networks are deployed, we can expect to see even more innovative applications of this technology

What are the common challenges?

Manufacturing and Industrials: Let’s dive deeper into IT and OT convergence

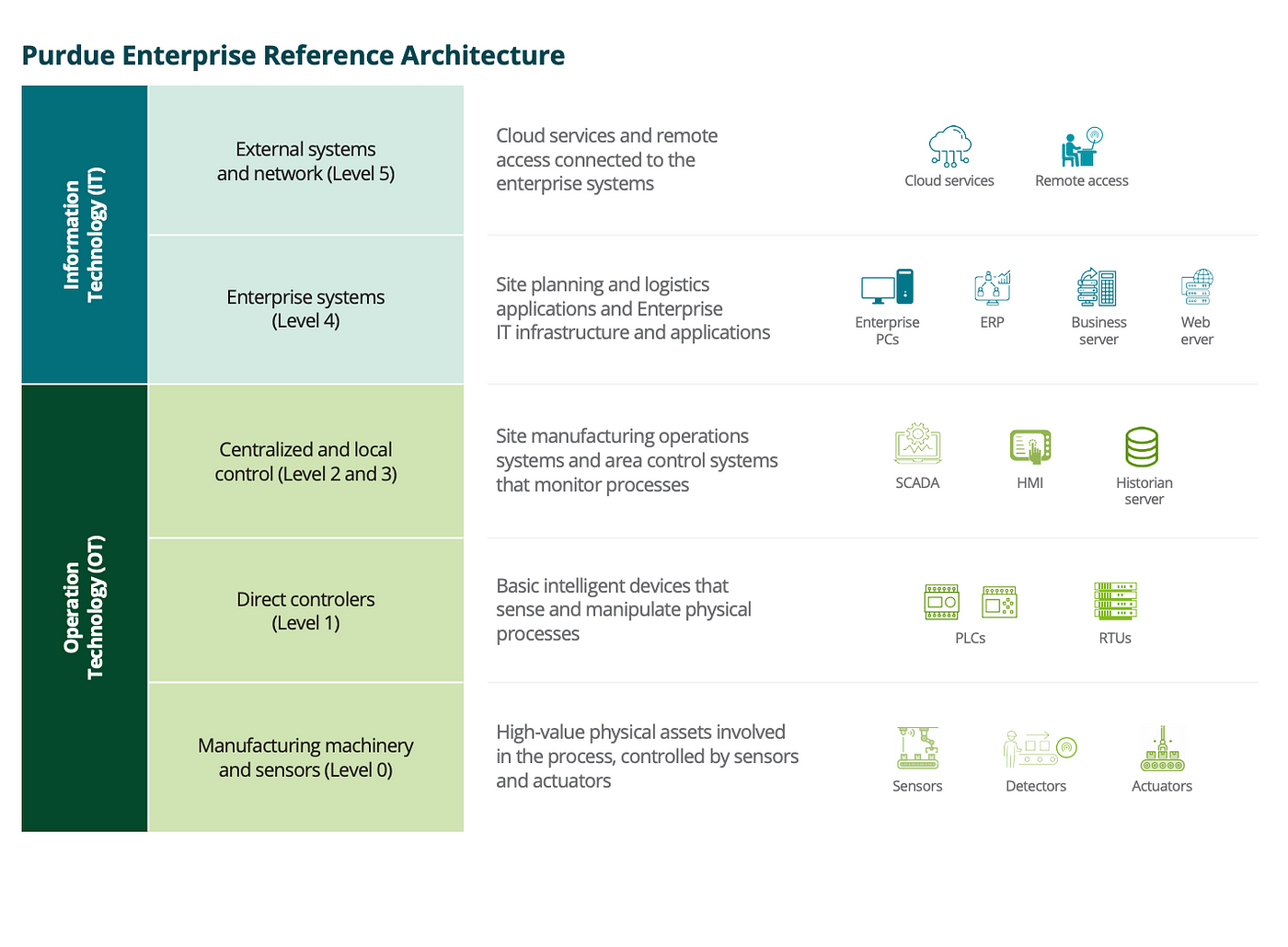

OT and IT are two distinct but increasingly interconnected areas of technology. OT systems are responsible for monitoring and controlling physical processes and devices, while IT systems are responsible for storing, processing, and delivering information. While OT and IT have traditionally been separate, the rise of Industry 4.0 is driving the convergence of these two technologies. As OT systems become more connected and integrated with IT systems, it is becoming increasingly important for organizations to have a clear understanding of the differences between OT and IT.

Here are some additional details about the key differences between OT and IT:

- Purpose: OT systems are designed to monitor and control physical processes and devices, while IT systems are designed to store, process, and deliver information. OT systems are typically used in industrial settings, while IT systems are typically used in office settings.

- Focus: OT systems are focused on the physical world, while IT systems are focused on the digital world. OT systems are typically used to monitor and control physical devices, such as machinery and equipment. IT systems are typically used to store, process, and deliver information, such as documents, emails, and files.

- Systems: OT systems are typically proprietary and closed, while IT systems are typically open and standardized. OT systems are often developed by specific vendors for specific applications. IT systems are often developed by multiple vendors and are designed to be compatible with a wide range of applications.

- Users: OT systems are typically used by engineers and technicians, while IT systems are typically used by business users and IT professionals. OT systems require a deep understanding of physical processes and devices. IT systems require a basic understanding of computers and networks.

- Security: OT security is often focused on physical security, while IT security is often focused on cyber security. OT systems are typically located in physically secure areas, such as control rooms. IT systems are typically located in less secure areas, such as offices.

- Risks: OT risks typically relate to physical damage or disruption, while IT risks typically relate to data loss or theft. OT systems can be damaged by physical events, such as fires or floods. IT systems can be hacked or infected with malware.

- Benefits: OT systems can improve efficiency and productivity, while IT systems can improve communication and collaboration. OT systems can help to automate tasks and improve decision-making. IT systems can help to share information and improve communication between different departments and teams.

- Challenges: OT systems can be difficult to integrate with IT systems, while IT systems can be difficult to manage and secure. OT systems are often designed to work independently of IT systems. IT systems are often complex and require specialized skills to manage and secure.

The convergence of OT and IT is creating new opportunities and challenges for organizations. By understanding the key differences between OT and IT, organizations can better prepare for the challenges of the future.

IT/OT Do they converge AND what are the challenges?

One industrial data platform is what the companies are looking to build

here are some key aspects that need to be detailed to be considered in the target architecture and the implementation roadmap:

Capabilities and Apps Layer

- Apps covering specific use cases: These apps should be designed to address specific business needs, such as predictive maintenance or automated error detection. They should build upon standardized platform functionality to ensure that they are scalable and secure.

- Apps provided by a third party or platform provider: These apps can provide additional functionality and features that are not available in the core platform. They can be accessed via an app store, which makes it easy for users to find and install the apps they need.

Analytics and Data Platform

- Highly scalable services: The analytics and data platform should be highly scalable to handle the volume and variety of data that is generated by industrial devices. It should also be secure to protect sensitive data from unauthorized access.

- Standardized (self-service) reporting, analytics, visualization, or location services: These services should be available via API to all apps. They should use best-in-class algorithm libraries to provide accurate and insightful analysis of data.

- Integration and harmonization of data: The analytics and data platform should be able to integrate and harmonize data from a variety of sources, including machines, sensors, and people. This will ensure that all data is available for analysis and that it can be used to make informed decisions.

Operations Services

- Interface to enterprise-level software: The analytics and data platform should be able to interface with enterprise-level software, such as ERP, SCM, PLM, or CAD. This will allow users to access data from the platform in a format that is compatible with their existing systems.

- Data routing and exchange with edge devices and machines: The analytics and data platform should be able to route and exchange data with edge devices and machines. This will allow users to collect data from remote locations and process it locally, which can improve performance and reduce latency.

- Data routing, prioritization, and storage enabled by on-site processing and storage within edge gateways: The analytics and data platform should be able to route, prioritize, and store data on-site within edge gateways. This will improve performance and reduce latency for data that needs to be processed locally.

- Easy integration of devices into the platform via plug and play: The analytics and data platform should be easy to integrate with new devices. This can be done via plug-and-play, which makes it easy for users to add new devices to the platform without having to write any code.

By considering these key aspects, organizations can develop a target architecture and implementation roadmap that will help them to achieve their business goals.

Regards,

Sidhartha Sharma

Leave a Reply